|

3-Way High Efficiency Speaker

3-Way High Efficiency Speaker

(Lavoce, Dynaudio, Foster 3-way. October-2023)

LCR MTM 3-Channel Speaker

LCR MTM 3-Channel Speaker

(Three MTM Speakers in One. July-2023)

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

(Minimus 7 and Dayton Audio. Spring-2022)

2-Way Ribbon Tweeter Speakers

2-Way Ribbon Tweeter Speakers

(Vifa and Pioneer. May-2020)

Transmission Line Speakers

Transmission Line Speakers

(Aborted attempt at a TL. September-2012)

Acoustic Research AR-4x Rehab

Acoustic Research AR-4x Rehab

(Rehab of a garage sale find. January-2016)

Infinity RS-4000 Rehab

Infinity RS-4000 Rehab

(Rehab of a garage sale find. June-2015)

Polaris

Polaris

(A tall, thin, upwards firing omnidirectional speaker. May-2010)

Shiva_PR15

Shiva_PR15

(A powered subwoofer using a 12" driver and 15" passive radiator. Jan-2010)

Can-Less

Can-Less

(A computer speaker; redux. December-2005)

Can-Can

Can-Can

(A computer speaker in a light canister. Jan-2005)

Sonosub

Sonosub

(10" vented subwoofer in a cardboard tube, powered by a Parapix amp. May-1999)

MTM Center Channel Speaker

MTM Center Channel Speaker

(A Madisound design. Nov-1997)

2-way Surround Speakers

2-way Surround Speakers

(5" woofer and 1" tweeter. July 1997)

3-piece mini system

3-piece mini system

(6" DVC bass module mated to 4" car speaker. June 1997)

3-way Vented Floorstanding Speaker

3-way Vented Floorstanding Speaker

(vented 10" woofer, 5" mid and 1" tweeter in a 4

ft tower. Summer 1995)

NHT1259 Subwoofer

NHT1259 Subwoofer

(A 12" woofer in a sealed architectural pedestal. Winter 1994-95)

Inexpensive Speaker Stands

Inexpensive Speaker Stands

(Particle board, sand and spray paint. Fall 1994)

2-way satellite

2-way satellite

(6.5" woofer and 1" tweeter. Summer/Fall 1994)

| Audio Electronics Related Projects |

900 MHz Audio Receiver

900 MHz Audio Receiver

(Better use for bad headphones. Jan-2008)

Buster - A Simple Guitar Amp

Buster - A Simple Guitar Amp

(Perfect for the beginner. Jan-2010)

A PC-based Audio Console

A PC-based Audio Console

(Use a PC to play tunes. Jan-2010)

LM-12 Amp

LM-12 Amp

(Bridged LM-12 opamps. Aug-2003)

CeeDeePee

CeeDeePee

(A CD player and FM tuner from spare computer parts. Oct-2002)

Quad 2000 4-Channel Amp

Quad 2000 4-Channel Amp

(Premade modules by Marantz. May-1998)

Zen Amp and Bride of Zen Preamp

Zen Amp and Bride of Zen Preamp

(by Nelson Pass. Apr-1997)

Using Wood in Speakers FAQ

Using Wood in Speakers FAQ

(Work in progress)

MDF FAQ for speaker builders

MDF FAQ for speaker builders

Woodworking Tools for the DYIer

Woodworking Tools for the DYIer

(HomeTheaterHiFi.com Oct-1998)

Some Thoughts on Cabinet Finished for DIY Speakers

Some Thoughts on Cabinet Finished for DIY Speakers

Large Grills Made Easy

Large Grills Made Easy

Some Parts Suppliers

Some Parts Suppliers

(Outdated)

DIY Audio Related URLs

DIY Audio Related URLs

Veneering Primer

Veneering Primer

(by Keith Lahteine)

How to get a Black Piano Finish

How to get a Black Piano Finish

(by DYI Loudspeaker List members)

Sonotube FAQ

Sonotube FAQ

(by Gordon McGill)

Excerpts from the Bass List

Excerpts from the Bass List

(Oldies but Goodies)

DIY Loudspeaker List Archives

DIY Loudspeaker List Archives

|

|

3-Way High Efficiency Speaker

3WHE stands for "3-way high efficiency". This speaker is my attempt at my holy grail - a small bookshelf speader with deep bass extension and high efficiency at a reasonable cost. To accomplish this requires just the right woofer and I found it. The secret sauce to making this speaker work is the Lavoce WAF061.80 6.5 inch woofer. When modeled, I got some really impressively small vented boxes - almost too good to be true. I ordered 2 from Parts Express. They arrived nicely packed in a cardboard box. These are superbly made and very heavy for there size. Mounted on a test baffle and measuring in-room, they looked like the real deal.

Usually for a woofer of this size, a 2-way would do the trick. But I already had a pair of Dynaudio D52 soft dome mids looking for a home. These are high sensitivity mids that would keep up with the Lavoce woofers. To round out the high end, I used a pair of Foster ET100 ribbon. Together, this had the making of a really nice 3-way. Here are PDFs for each of the drivers used:

- Lavoce WAF061.80 woofer spec

- Lavoce WAF061.80 woofer response

- Dynaudio D52 spec

- Foster ET100 spec

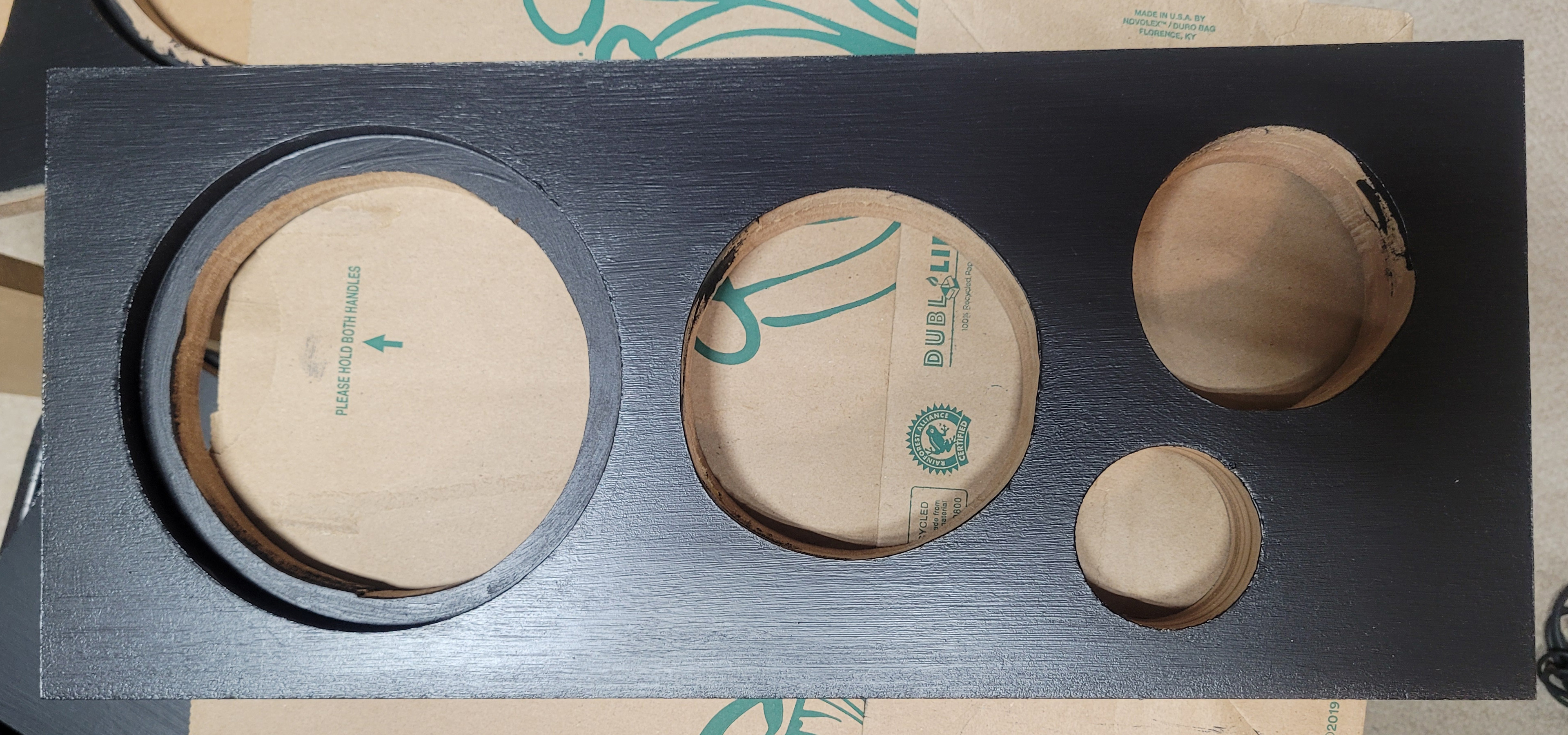

Since the box is going to be relatively small, I wanted to minimize the front baffle size. The size of the woofer dictated the width of the baffle. The 5.5 inch long port influenced the minimum depth of the box. The height was a function of all the drivers and 2 inch port diameter. Box and port modeling showed that the port length was not very critical - the net effect on the F3 point varied minimally with port and box size so I ended up with a box that made sense based partly on the materials I had on-hand. The front baffle is 2 layers of MDF - 3/4 and 1/2. The 1/2 inch allowed me to recess mount the woofer which a 1/2 inch thick flange. The mid and tweeter are flush mounted to the baffle. The other 5 sides are 3/4 inch MDF. Where it mattered, I took the time to cut perfect circles with a jig; otherwise the circles were cut with a jigsaw.

The tweeter required a little extra work. The shape of the tweeter is unusual and it would be difficult to cut an opening in MDF for a snug fit. I therefore asked my son to create an adapter that would convert the tweeter's irregular shape into a standard round fitting. The adapter was 3D printed and worked like a charm.

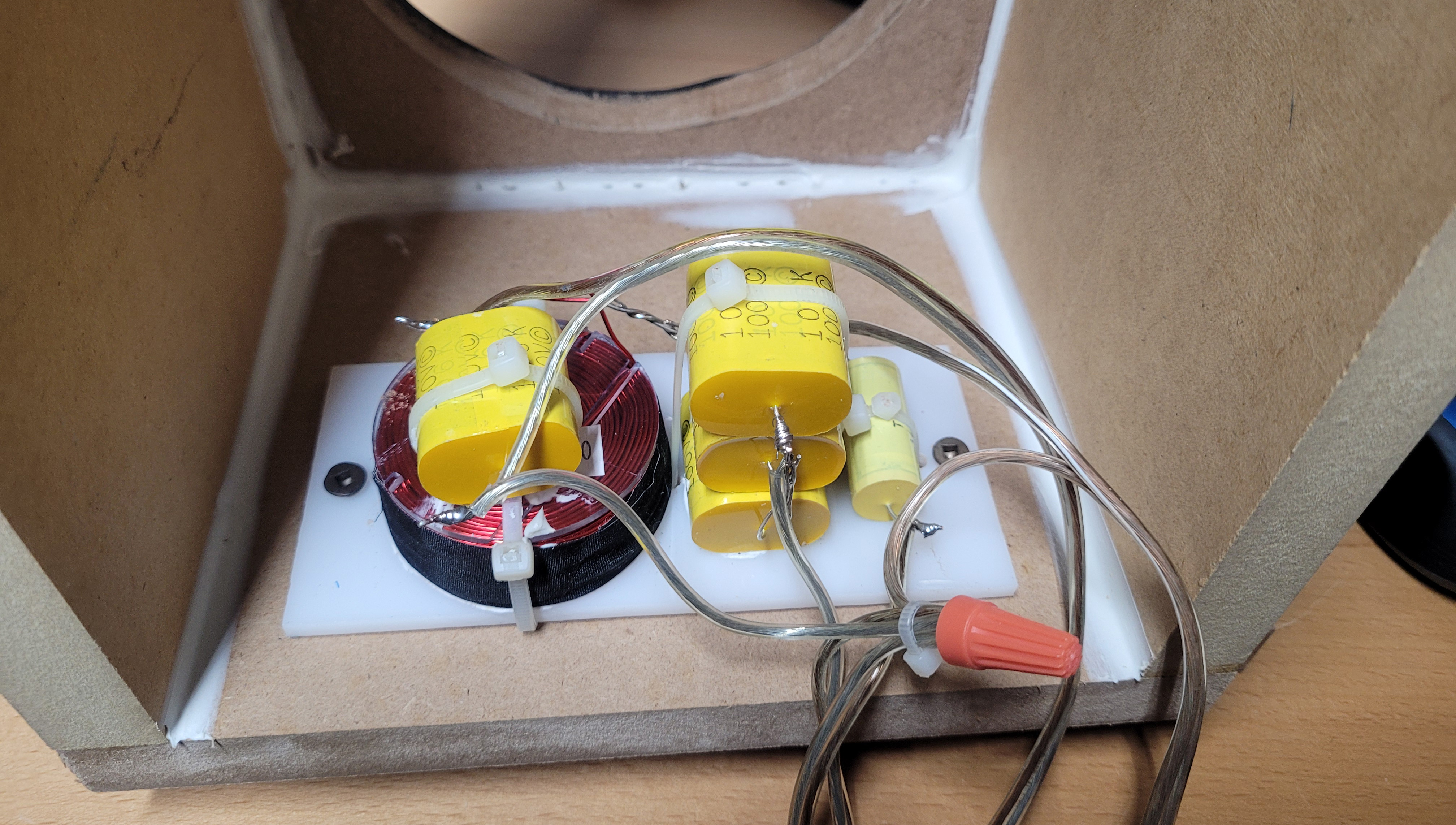

The crossover is really simple. Simple is nice if you can get away with it. The tweeter has a single 3uF cap for the high filter. The mid has a single 30uF (3 x 10uF) cap for a high pass. There's no low pass - the D52 is so well behaved I just let it run open on the high end. The woofer has a second order 10uF cap and 2.5mH inductor for a LP. The components are zip-tied and caulked to a piece of polycarbonate which is screwed to the bottom of the case.

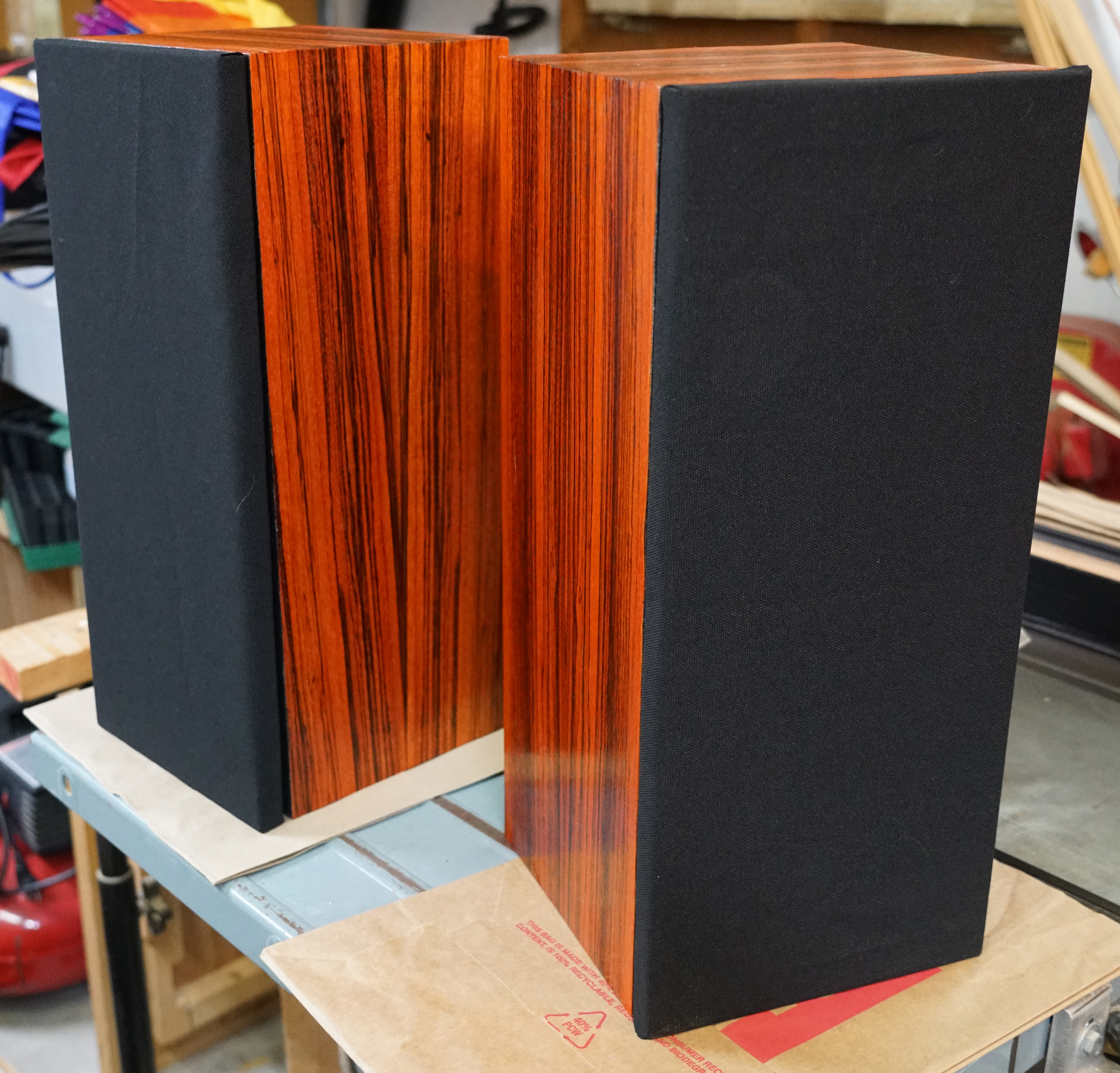

For visual appeal, I painted the baffle black and made the grill from plywood and black acoustic fabric.

The cabinet is veneered with zebrawood - bookmatched down the center and then dyed orange and top coated with a semi-gloss urethane.

This is very much a bookshelf speaker. Placed against a wall, the sound is authoratative in the bass, smooth in the vocals and not tiring in the highs. They are efficient and fill the room effortlessly.

Overall, I'm extremely happy with these speakers on all levels.

|

|

21-October-2023

Note: The

contents in these pages are provided without any guarantee,

written or implied. Readers are free to use them at their

own risk, for personal use only. No commercial use is allowed

without prior written consent from the author.

|

|

|