|

2-way

Satellite Speakers

Introduction

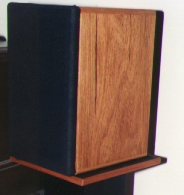

My 2-way satellite speakers seen here from the front and back

were built in the summer and fall of 1994.

Due to a number of extended business trips, they were built

in stages as time permitted. The original intent was to tune

the crossover myself, starting with a basic, textbook, formula

driven circuit. But as my travels came to an end, all I wanted

to do was sit back, relax and enjoy them. And so the original

textbook crossover remained in place for about a year.

My 2-way satellite speakers seen here from the front and back

were built in the summer and fall of 1994.

Due to a number of extended business trips, they were built

in stages as time permitted. The original intent was to tune

the crossover myself, starting with a basic, textbook, formula

driven circuit. But as my travels came to an end, all I wanted

to do was sit back, relax and enjoy them. And so the original

textbook crossover remained in place for about a year.

In late

1995, I took some time and measured these speakers with a

Radio Shack SPL meter. The resulting numbers confirmed the

audible rising high end that I found annoying. It also showed

a 5dB dip at 4 KHz which I did not hear. I decided to ignore

the dip which happens to be close to the intended crossover

frequency of 4500 Hz and was thus most likely a crossover

bug. As for the rising high end, I eventually did minimal

work by placing a 4 ohm resistor in series with tweeter. The

resulting sound was much more to my liking and they remain

in this state to this day. The imaging is quite good, and

when used with my NHT 1259 based

subwoofer they sound super, IMHO.

NOTE - It's

important to emphasize that this design is far from perfect.

It represents what happens when a novice tries to built speakers

from scratch with few tools and relatively little knowledge

beyond the fundamentals. The lessons learned are as much on

the how-to as on the how-not-to. But perhaps most important

of all, the overall satisfaction of creating something that,

in my humble and admitedly biased opinion sounds far better

then most mass-market speakers makes the project worth the

time I invested.

The drivers

For simplicity,

I went with a sealed box design. The woofer used is an

ACI AC7. This is a 6.5 inch, 8 ohm treated paper woofer

with a foam surround. A nearly identical woofer is Vifa's

C17WG-08. In a small sealed enclosure of a bit under 0.6 cubic

feet, the calculated F3 is 61 Hz. Actual measurement confirmed

a final F3 in the 60's. In use, the satellite and subwoofer

are driven via an active crossover set at 100 Hz so the satellite's

low end response is not very crucial.

The tweeter

used is a Vifa D25AG-05-06. This is a 6 ohm, aluminum alloy

dome tweeter. The Vifa D25AG-35-06 is similar but has a lower

Fs (1500 Hz versus 850 Hz). Since I used a relatively high

crossover frequency of 4500 Hz, this was not an issue. The

tweeter's high end response is well over 20 KHz.

The crossover

As mentioned

earlier, the crossover is nothing to be proud of; yet the

results are quite pleasing to my ears. The circuit is a 4th

order Linkwitz-Riley design consisting of two inductors and

two capacitors in each of the tweeter and woofer networks.

The tweeter network also has an series 4 ohm resistor as mentioned

earlier. Component values for the chosen crossover value of

4500 Hz can be derived from cookbook formulas such as those

in the Loudspeaker Design Cookbook by Vance Dickason.

The Radio

Shack SPL meter I used to measure the speaker's SPL is spec'ed

at 32 Hz to 10 KHz +/- 3 dB. Using a Stereophile test CD,

the speaker's response is 90 dB +/- 3 dB from 80Hz to 10 KHz

with a 2.83V input measured on-axis at 1 meter, except for

a room (floor) notch in the vicinity of 160 to 200 Hz where

it is down 6 dB. The previously mentioned dip at 4 KHz actually

falls within the +/- 3 dB error range. In the narrower range

from 400 Hz to 10 KHz, the response is much flatter at 92

dB +/- 1.5 dB with the exception of the notch at 4 KHz. Below

80 Hz, the response drops another 0.5 dB at 63Hz before falling

off at roughly 12 dB per octave as expected. All-in-all, the

response is quite respectable, especially when one considers

that these are in-room measurement.

The box

The enclosure

is made of 3/4 inch MDF and is veneered with rosewood on five

sides. The back is painted flat black. The external dimensions

(in inches) are roughly 9.75 wide by 15.625 tall by 10.75

deep. Each panel of the box was veneered separately after

first dry-fitting all the pieces. The two panels that make

up the left and right sides are rabbetted on the top and bottom

so that the top and bottom pieces sit partially in the rabbet.

This leaves a missing square that is filled in with a piece

of solid cherry which is then rounded over. Hopefully, this

picture will show what I mean. Notice the solid cherry

piece on the four corners of the enclosure. The reasons for

using the solid cherry are (1) to provide an easy surface

to round over the edges and (2) to prevent exposed end grain

on the veneer which could be easily damaged. The enclosure

is made of 3/4 inch MDF and is veneered with rosewood on five

sides. The back is painted flat black. The external dimensions

(in inches) are roughly 9.75 wide by 15.625 tall by 10.75

deep. Each panel of the box was veneered separately after

first dry-fitting all the pieces. The two panels that make

up the left and right sides are rabbetted on the top and bottom

so that the top and bottom pieces sit partially in the rabbet.

This leaves a missing square that is filled in with a piece

of solid cherry which is then rounded over. Hopefully, this

picture will show what I mean. Notice the solid cherry

piece on the four corners of the enclosure. The reasons for

using the solid cherry are (1) to provide an easy surface

to round over the edges and (2) to prevent exposed end grain

on the veneer which could be easily damaged.

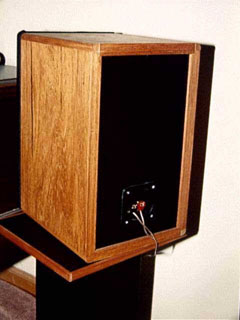

The back

MDF panel is rabbetted into all four sides (left, right, top,

bottom) and recessed 1/4 inch. It is finished with black spray

enamel paint plus a clear topcoat. The terminal cup is mounted

with four screws and caulked from the inside to seal the opening

as tightly as possible. The front looks like this without the grill on. The baffle is rabbetted

into the four sides and sits flush with them. The four whitish

rectangular objects at the corners are velcro pads I stappled

into the MDF to hold the grill. They work surprisingly well,

though it lacks that finished look !

The back

MDF panel is rabbetted into all four sides (left, right, top,

bottom) and recessed 1/4 inch. It is finished with black spray

enamel paint plus a clear topcoat. The terminal cup is mounted

with four screws and caulked from the inside to seal the opening

as tightly as possible. The front looks like this without the grill on. The baffle is rabbetted

into the four sides and sits flush with them. The four whitish

rectangular objects at the corners are velcro pads I stappled

into the MDF to hold the grill. They work surprisingly well,

though it lacks that finished look !

I forgot

to recess the drivers during construction so that they could

be flush mounted, so I ended up just surface mounting them.

This meant that the grill had to allow driver clearance. The

grill is just a piece of MDF with a center rectangle removed.

Acoustical fabric is then stretched over the unit and stappled

on the back side. Finally the corresponding velcro pads are

stappled in place. All exterior veneer surfaces are finished

with Danish oil and wax.

The crossover

is build on a small board and screwed to the back of the enclosure

on the inside. Internal bracing consists of just some reinforcement

along the top and bottom inside edges where the cherry is.

These were the weakest points in the original box. No other

bracing was added as the box is fairly small. The result is

a very strong, stiff and heavy box.

The result

Simply put,

I like them. The addition of subwoofers really helps the low

end, but that alone doesn't explain the nicely detailed sound.

I'm generally not a fan of metal domes, and prefer the textile

ScanSpeak dome in my 3-way speakers

over the Vifa. Prior to adding the tweeter series resistor,

I found the speakers tiring after long periods of listening.

Damping the high end with the resistor cured the problem and

I now find myself comfortably listening to hours of music

through these speakers

Lessons learned

I like to

make things. I also like to learn from my projects. This speaker

was no exception. I made several mistakes such as the mouting

of the crossover which made it difficult to tweak later (this

inspired the crossover mounting in my aforementioned 3-way

speaker which I built later). I forgot to mount the drivers

flush; did not account for the grill's attachment to the baffle

(hence the velcro); and did not pay as much attention to the

crossover as I should have. I learned to apply veneer with

a household iron; realize nuances in the music I listen to

which I had previously missed (due to really poor speakers)

and decided to better plan future projects so that I give

them the attention they need. I also believe that I lucked

out on the crossover and that it could have come out much

worse. But on the plus side, this project enticed me to once

again enjoy listening to music.

In Closing

I've purposely

left out the details of the speaker since the methodology

I used and the results I got are not what a DIYer should strive

for. There are many other speakers on the net, far better

than this, for beginners to build. In fact, it is for this

reason that I had neglected to complete the write up of this

speaker project for so long. I present this abbreviated description

NOT to show how to build speakers; rather I present it as

a summary of what I did so that others can learn from my mistakes.

I used this project as a starting point to built other speakers;

and like all things I build, I tried to learn bits and pieces

from the work itself. Maybe others will get something out

of this as I have :)

Update (7/97)

As of this

writing, I am in the process of completing some new speakers

and have thus taken the time to update this pair. I particularly

disliked the existing velcro grill; they were surprisingly

difficult to remove and failed the "completeness"

test. I decided to retrofit the grill with traditional socket

grill connectors from Madisound.

This involved gluing triangular MDF corners to the grill to

provide enough surface area to hold the sockets. The balls

are mounted to the baffle. Whereas the grill fabric was previously

stappled in place, this time, I added hot glue. Here is the

retrofitted grill and speaker. As of this

writing, I am in the process of completing some new speakers

and have thus taken the time to update this pair. I particularly

disliked the existing velcro grill; they were surprisingly

difficult to remove and failed the "completeness"

test. I decided to retrofit the grill with traditional socket

grill connectors from Madisound.

This involved gluing triangular MDF corners to the grill to

provide enough surface area to hold the sockets. The balls

are mounted to the baffle. Whereas the grill fabric was previously

stappled in place, this time, I added hot glue. Here is the

retrofitted grill and speaker.

|