|

3

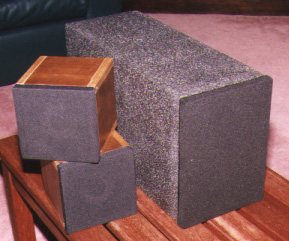

Piece Mini System

Introduction

As part

of my on-going attempt to use up "stuff" I've collected

over the years, I'd deciced to build a three piece mini speaker

system consisting of two mini satellite cubes and a bass module.

The system would be used in a non-critical setting with a

less-than-ideal setup such as a kitchen. High SPL is not required.

The goal is to create something usable, cheaply, without placing

much emphasis on overall quality. Net audio quality will nonetheless

likely be on-par with similar mass-market systems selling

at higher prices.

As part

of my on-going attempt to use up "stuff" I've collected

over the years, I'd deciced to build a three piece mini speaker

system consisting of two mini satellite cubes and a bass module.

The system would be used in a non-critical setting with a

less-than-ideal setup such as a kitchen. High SPL is not required.

The goal is to create something usable, cheaply, without placing

much emphasis on overall quality. Net audio quality will nonetheless

likely be on-par with similar mass-market systems selling

at higher prices.

The main

parts I wanted to "recycle" were a pair of 4 inch

Kenwood car speakers left over from my old car. For the box,

I had various decently sized pieces of 5/8 inch particle board

suitable for the bass module and smaller pieces of MDF for

the cubes. Leftover grill fabric, veneer, and crossover components

make up the rest of the spare parts list. The main

parts I wanted to "recycle" were a pair of 4 inch

Kenwood car speakers left over from my old car. For the box,

I had various decently sized pieces of 5/8 inch particle board

suitable for the bass module and smaller pieces of MDF for

the cubes. Leftover grill fabric, veneer, and crossover components

make up the rest of the spare parts list.

The drivers

The 4 inch

car speaker is a 4 ohm Kenwood unit of unknown model. I've

had these driver for over 10 years and they've served their

purpose well in my old car. After my car stereo was stolen,

I removed these since the new stereo only powered the rear

speakers. These drivers have a "whizzer" cone and

a silver-colored dust cap. They sound about as good as cheap

"full range" car speakers can sound, which is not

a whole lot better than your average low budget boom box.

The woofer

is a "special" from Parts

Express. This is a 6 inch dual voice coil shielded driver

by Pyle with a coated paper cone. The specs include : Fs =

56 Hz, SPL = 89 dB, Vas = 0.46 cu. ft., Qms = 7.98, Qes =

0.44, Qts = 0.42, Impedance = 8 ohms per coil, cost = $17.50.

I didn't care for the shielding, which wasn't very good. Overall

quality was acceptable.

The crossover

I wanted

to keep the crossover as simple as possible. Since the speakers

would primarily play the role of creating ambience, why spend

the time to get everything just right ? It just wasn't worth

the effort given the quality of the components in use.

My starting

point was a 10 mH iron core inductor and some electrolytic

capacitors left over from an old subwoofer passive filter.

I installed the inductor in the bass module and took measurements.

I then measured the cubes and noted that their response fell

from about 160 Hz. This is a bit high to avoid directionality

but it would have to do. With some experimentation, I came

up with a second order low pass filter consisting of a 10

mH inductor and a 100 mfd electrolytic capacitor. The high

pass was only a 160 mfd (actually 100 + 50 + 10) electrolytic

capacitor which combines with the driver's natural rolloff.

The box

Each cube

is an MDF box sized just big enough to hold the 4 inch driver.

The external dimension, excluding the grill, measured (in

inches) 5.5 wide, 5.5 high and 5 deep. The grill added another

5/8 inch to the depth. All panels are glued and screwed together.

The interior seams are caulked. The four side edges are removed

and replaced with solid poplar, lightly chamfered to soften

the edge. The sides are veneered with imbuya - a wood with

a walnut-like look - and finished with danish oil and polyurethane.

The grill

consists of a piece of plywood with the center removed. Grill

fabric is stretched over the frame, then stappled and hot

glued on the reverse side. The entire grill is subsequently

hot glued to the baffle. No provisions are made to allow removal

of the grill other than to pry it off the baffle. Hot glue

is not all that strong and much easier to deal with than trying

to add ball & socket connectors that won't have room to

fit !

The bass

module was made of 5/8 inch particle board (MDF would have

been better but I only had small pieces which were used on

the cubes). The exterior dimensions in inches are 18.25 deep,

10.25 wide and 7.25 high. This gave an internal volume of

about 0.5 cubic foot, not counting the port and driver volume.

Like the cubes, only glue and screws holds this box together.

Inner seams are caulked but there is no internal bracing.

The driver is recess mounted to fit flush against the baffle

and is located off-center so that a 1.5 inch (inside) diameter

cardboard port tube can also be mounted to the baffle. The

port is slightly longer than 2 inches. A grill similar to

the ones used on the cubes is used for the bass module except

that ball & socket connectors are used for easy grill

removal.

On the rear

of the unit, an 8 terminal speaker cup is mounted to provide

left and right channel input sand high pass filtered outputs

for the cubes. All crossover components are mounted inside

the bass module and can be accessed by removing the terminal

cup.

Prior to

applying the finish, I sealed all cracks and voids in the

particle board with wood putty. I also used the putty to even

out some misaligned joints. For the finish, I first sprayed

all sides with flat black Rustoleum brand spray paint. This

is my favorite spray paint as it adheres very well to all

types of surfaces including particle board. For the four large

sides, I sprayed on Krylon's two-part "Make It Stone!"

finish in Obsidian. Obsidian is black with white specks for

a granite look and feel. The first part gives the color and

texture while the second part is a clear protective topcoat.

The front and back only had the original flat black paint

but they too got the clear topcoat. The overall effect is

quite nice and best of all, it's very simple and quick to

apply.

The result

Measurements

taken from a Radio

Shack SPL meter showed the combined units to be flat (+/-

3 dB in-room) from about 63 Hz to 1600 Hz. Then to about 4000

Hz, there is a 3dB rise, some of which is probably due to

the baffle step. Between 5000 Hz and 8000 Hz, response rises

another 3 dB and has a distinctly "whizzer cone"

sound. I considered removing the "whizzer" cone

but if I didn't do a clean enough job with the knife, it would

probably have sounded even worse. Luckily, the sound was not

harsh. Besides, I reasoned that once in use, the chance of

actually listening to the cube inline with the driver was

small thus its effects would be much less noticeable.

Clearly

this is not a sonic masterpiece by any means but it will do

nicely for cheap, non-intrusive sound with decent bass. And

therein lies the main difference between it and the mass market

cube + air-blowing bass modules. Whereas this bass module

is a bit larger at 1/2 cu. ft., it also delivers quality bass.

There's no wind noise or boom so often found in compact systems

today. So for a total cost of about $25 - mainly for the woofer

and spray paint - I now have a mini system that sounds fairly

decent.

Update

8/97

Two factors

made me update the cubes - they were ugly and my wife liked

the granite look on the bass module. Since I still had about

one third of the granite spray left, I sprayed the cubes to

match the bass module. Goodbye wood look, hello matching set

!

29-September-2000

Note: The

contents in these pages are provided without any guarantee,

written or implied. Readers are free to use them at their

own risk, for personal use only. No commercial use is allowed

without prior written consent from the author.

|