|

3-Way High Efficiency Speaker

3-Way High Efficiency Speaker

(Lavoce, Dynaudio, Foster 3-way. October-2023)

LCR MTM 3-Channel Speaker

LCR MTM 3-Channel Speaker

(Three MTM Speakers in One. July-2023)

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

Mini7bt - A Minimus 7 Portable Bluetooth Speaker

(Minimus 7 and Dayton Audio. Spring-2022)

2-Way Ribbon Tweeter Speakers

2-Way Ribbon Tweeter Speakers

(Vifa and Pioneer. May-2020)

Transmission Line Speakers

Transmission Line Speakers

(Aborted attempt at a TL. September-2012)

Acoustic Research AR-4x Rehab

Acoustic Research AR-4x Rehab

(Rehab of a garage sale find. January-2016)

Infinity RS-4000 Rehab

Infinity RS-4000 Rehab

(Rehab of a garage sale find. June-2015)

Polaris

Polaris

(A tall, thin, upwards firing omnidirectional speaker. May-2010)

Shiva_PR15

Shiva_PR15

(A powered subwoofer using a 12" driver and 15" passive radiator. Jan-2010)

Can-Less

Can-Less

(A computer speaker; redux. December-2005)

Can-Can

Can-Can

(A computer speaker in a light canister. Jan-2005)

Sonosub

Sonosub

(10" vented subwoofer in a cardboard tube, powered by a Parapix amp. May-1999)

MTM Center Channel Speaker

MTM Center Channel Speaker

(A Madisound design. Nov-1997)

2-way Surround Speakers

2-way Surround Speakers

(5" woofer and 1" tweeter. July 1997)

3-piece mini system

3-piece mini system

(6" DVC bass module mated to 4" car speaker. June 1997)

3-way Vented Floorstanding Speaker

3-way Vented Floorstanding Speaker

(vented 10" woofer, 5" mid and 1" tweeter in a 4

ft tower. Summer 1995)

NHT1259 Subwoofer

NHT1259 Subwoofer

(A 12" woofer in a sealed architectural pedestal. Winter 1994-95)

Inexpensive Speaker Stands

Inexpensive Speaker Stands

(Particle board, sand and spray paint. Fall 1994)

2-way satellite

2-way satellite

(6.5" woofer and 1" tweeter. Summer/Fall 1994)

| Audio Electronics Related Projects |

900 MHz Audio Receiver

900 MHz Audio Receiver

(Better use for bad headphones. Jan-2008)

Buster - A Simple Guitar Amp

Buster - A Simple Guitar Amp

(Perfect for the beginner. Jan-2010)

A PC-based Audio Console

A PC-based Audio Console

(Use a PC to play tunes. Jan-2010)

LM-12 Amp

LM-12 Amp

(Bridged LM-12 opamps. Aug-2003)

CeeDeePee

CeeDeePee

(A CD player and FM tuner from spare computer parts. Oct-2002)

Quad 2000 4-Channel Amp

Quad 2000 4-Channel Amp

(Premade modules by Marantz. May-1998)

Zen Amp and Bride of Zen Preamp

Zen Amp and Bride of Zen Preamp

(by Nelson Pass. Apr-1997)

Using Wood in Speakers FAQ

Using Wood in Speakers FAQ

(Work in progress)

MDF FAQ for speaker builders

MDF FAQ for speaker builders

Woodworking Tools for the DYIer

Woodworking Tools for the DYIer

(HomeTheaterHiFi.com Oct-1998)

Some Thoughts on Cabinet Finished for DIY Speakers

Some Thoughts on Cabinet Finished for DIY Speakers

Large Grills Made Easy

Large Grills Made Easy

Some Parts Suppliers

Some Parts Suppliers

(Outdated)

DIY Audio Related URLs

DIY Audio Related URLs

Veneering Primer

Veneering Primer

(by Keith Lahteine)

How to get a Black Piano Finish

How to get a Black Piano Finish

(by DYI Loudspeaker List members)

Sonotube FAQ

Sonotube FAQ

(by Gordon McGill)

Excerpts from the Bass List

Excerpts from the Bass List

(Oldies but Goodies)

DIY Loudspeaker List Archives

DIY Loudspeaker List Archives

|

|

Quad 2000 Four Channel Amplifier

Update (3-January-1999)

I finally

gave it a name - Quad 2000. After all, it's made of four MA-500

modules !

Update (3-December-1988)

The picture

of the chassis below shows the transformer mounted against

the rear panel. Immediately to the left is one of the amplifer

modules. Towards the top of each module is the input phono

plug connector. With the transformer mounted as shown, that

first monoblock obtained a significant amount of interference

from the transformer in the form of a low, but audible hum.

This problem was solved by mouting the transformer against

the side wall on the right (not shown in the picture below)

90 degress to its shown position. Doing so required that one

of the fuse blocks also be moved to the side wall to make

room for the transformer.

(Original text)

Here's a

quick look at my completed four channel amplifier using Marantz

amplifier modules.

The

modules were purchased in 1997 (February ?) and are presumably

the same ones used in the highly acclaimed

Marantz

MA500 monoblock amplifier and the discontinued Carver

AV-806x 6-channel home theater amplifier. Both are THX certified.

The former is rated at 125 watts in 8 ohms with <0.05%

THD while the latter is rated at 133 watts per channel into

8 ohms with <0.032 % THD+N. The Carver unit consists of

6 modules mounted side-by-side and is powered by two front-mounted

transformers (three modules per transformer).

For

this project, I used a case I already had - an LG-1925 from

Mark V Electronics. This case measures 5 inches tall by 17

inches wide by 11-1/2 inches deep - just tall enough for the

modules. The transformer is a custom-made unit from

Ulveco.

It's secondaries are rated at 92VCT @ 5A and 32VCT @ 0.34A.

At just under 5 inches in diameter, it too was able to fit

standing up.

This picture shows the position of the

various parts inside the case. In front of the transformer

are two fuse blocks (4 fuses each) from Parts

Express and two 8-position barrier/terminal strips from

Radio

Shack. Two 8 amp fuses protect each module's +/- 46V rails.

At the lower left, an additional 6 amp slow-blow fuse protects

the main AC line. Wiring is modular, to enable easy debugging

during construction. Each module has a 6 wire cable that's

tied to the bottom plate of the case with nylon ties. Each

of the 6 wires is connected either to the terminal strips

or the fuse block via screws. Not shown in the picture above

is an additional two wire cable from each module to light

the front panel module power LED via a 1 k-ohm resistor.

This picture shows the position of the

various parts inside the case. In front of the transformer

are two fuse blocks (4 fuses each) from Parts

Express and two 8-position barrier/terminal strips from

Radio

Shack. Two 8 amp fuses protect each module's +/- 46V rails.

At the lower left, an additional 6 amp slow-blow fuse protects

the main AC line. Wiring is modular, to enable easy debugging

during construction. Each module has a 6 wire cable that's

tied to the bottom plate of the case with nylon ties. Each

of the 6 wires is connected either to the terminal strips

or the fuse block via screws. Not shown in the picture above

is an additional two wire cable from each module to light

the front panel module power LED via a 1 k-ohm resistor.

Each

module is attached to both the bottom plate as well as the

rear plate. Everything needs to be well alligned for this

to work so I had a local metalworker do the drilling.

This is the rear of the unit. Note that

two of the four modules are "slave-only" and do

not have the RC-5 RCA connectors (which I opted not to use

anyway). Some of the black finish has been removed during

drilling.

This is the rear of the unit. Note that

two of the four modules are "slave-only" and do

not have the RC-5 RCA connectors (which I opted not to use

anyway). Some of the black finish has been removed during

drilling.

|

|

Holes were added to the bottom plate for

air circulation. Like the rear, some of the existing holes

are from previous projects that used to be in this case.

Holes were added to the bottom plate for

air circulation. Like the rear, some of the existing holes

are from previous projects that used to be in this case.

|

|

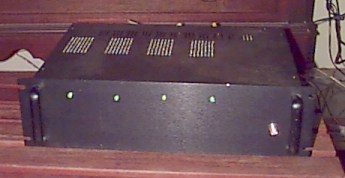

The top plate also had holes added - a

total of 364 ! - for circulation. They can be seen on this

picture of the completed unit. The front consists of four

green LEDs, one per module, and an orange neon power switch.

The green LEDs for the RC-5 capable "master" modules

are driven by the "power" signal. On the slave units,

the LED is driver by the board's regulated +15V line.

The top plate also had holes added - a

total of 364 ! - for circulation. They can be seen on this

picture of the completed unit. The front consists of four

green LEDs, one per module, and an orange neon power switch.

The green LEDs for the RC-5 capable "master" modules

are driven by the "power" signal. On the slave units,

the LED is driver by the board's regulated +15V line.

That's

all on this project. I've knowingly left out a lot of detail

for the simple lack of writing time. The amp has been about

a year in the works, with many months of indecision over what

to do and how to do it. Now that it's done, I can finally

sit back and enjoy them. The modules are outstanding and deserving

of their reputation in their commercial incarnation.

Thanks

I

have a lot of people to thank for making this possible, including

Joe Reynick, Art Povelones, Bob Garnaas, Dan Turner, Russell

Holm, Jeff Burger, Rex Gordon, Tom Williams, Michael Chizmar

and Will Law. I apologize for leaving anyone out. Thanks guys

!

29-September-2000

Note: The

contents in these pages are provided without any guarantee,

written or implied. Readers are free to use them at their

own risk, for personal use only. No commercial use is allowed

without prior written consent from the author.

|

|

|